Fast delivery

Global supplier

Innovative solutions

The Future of Manufacturing: Exploring New Plastic Injection Molds

Aug 05,2025

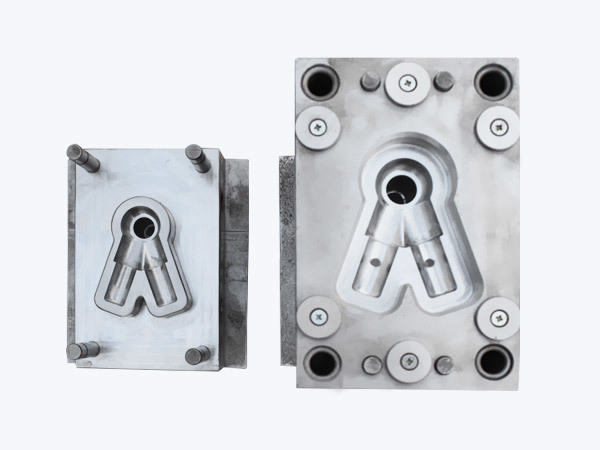

Plastic injection molding is a pivotal technology in the manufacturing sector, particularly in the production of complex plastic parts. New plastic injection molds represent the latest advancements in this field, offering enhanced performance, precision, and efficiency. These molds are designed to accommodate a wide variety of designs and applications, making them indispensable in numerous industries, from automotive to consumer goods.

One of the primary advantages of new plastic injection molds is their ability to produce high volumes of parts with consistent quality. Modern molds incorporate advanced materials and manufacturing techniques that improve durability and reduce wear over time. This results in lower maintenance costs and less downtime for manufacturers. Additionally, the precision of these molds allows for tighter tolerances, which is crucial for applications requiring exact specifications.

Another significant benefit of new plastic injection molds is their versatility. They can be customized to produce intricate designs that were previously challenging to achieve. This flexibility opens up opportunities for innovation in product development, enabling companies to experiment with complex geometries and innovative features without the constraints of traditional manufacturing methods. As industries evolve and consumer demands shift, having adaptable mold technology is essential for staying competitive.

Moreover, the development of new plastic injection molds is closely linked to sustainability. Manufacturers are increasingly focusing on eco-friendly practices, and modern molds can support the use of recycled materials and bio-based plastics. This not only helps reduce the environmental impact of production but also meets the growing consumer demand for sustainable products. Utilizing new molds can thus contribute to a company's corporate responsibility goals while still achieving high-quality outputs.

The integration of smart technology into mold design is another trend shaping the future of plastic injection molding. Advanced sensors and data analytics can monitor the molding process in real-time, allowing for immediate adjustments and ensuring optimal performance. This level of automation and insight helps manufacturers enhance their production efficiency and minimize waste, leading to more sustainable operations.

In summary, the emergence of new plastic injection molds is revolutionizing the manufacturing landscape. These molds not only enhance production efficiency and product quality but also support sustainability efforts and innovative design capabilities. As technology continues to advance, businesses that leverage the benefits of new plastic injection molds will be better positioned to meet the challenges of a dynamic market and consumer expectations. Adopting these innovative solutions is crucial for manufacturers aiming to thrive in an increasingly competitive environment.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.