Fast delivery

Global supplier

Innovative solutions

Unlocking Efficiency: The Benefits of FRP Molded Dies in Modern Manufacturing

Jun 09,2025

Unlocking Efficiency: The Benefits of FRP Molded Dies in Modern Manufacturing

Table of Contents

- Introduction to FRP Molded Dies

- What is Fiber-Reinforced Plastic (FRP)?

- Advantages of FRP Molded Dies in Manufacturing

- 1. Exceptional Durability

- 2. Cost-Effectiveness

- 3. Lightweight and Easy Handling

- 4. Versatility in Applications

- 5. Corrosion Resistance

- Applications of FRP Molded Dies in Various Industries

- Best Practices for Implementing FRP Molded Dies

- The Future of FRP Molded Dies in Manufacturing

- Frequently Asked Questions

- Conclusion

Introduction to FRP Molded Dies

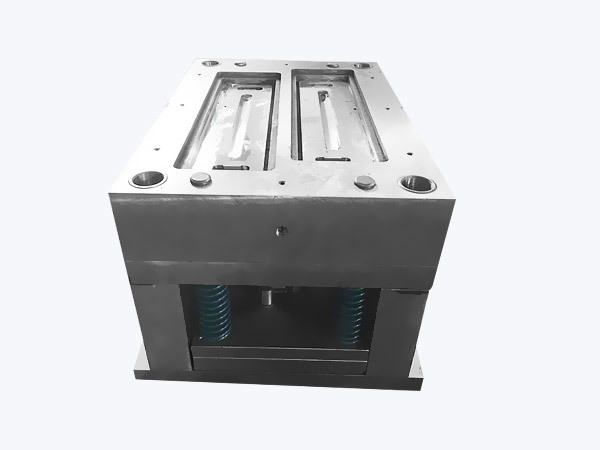

In a rapidly evolving manufacturing landscape, businesses are perpetually seeking innovative solutions to enhance productivity and reduce costs. **Fiber-Reinforced Plastic (FRP)** molded dies have emerged as a game-changing technology, offering exceptional benefits that align with modern manufacturing demands. This article delves deep into the **benefits of FRP molded dies**, outlining their features, advantages, and applicability across various industries.

What is Fiber-Reinforced Plastic (FRP)?

**Fiber-Reinforced Plastic (FRP)** is a composite material made of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The combination of these materials results in a lightweight yet incredibly strong and durable product. FRP is renowned for its ability to withstand harsh environments, making it a preferred choice for a variety of manufacturing applications. The fundamental properties of FRP include:

- **High Strength-to-Weight Ratio**

- **Chemical Resistance**

- **Thermal Stability**

- **Impact Resistance**

These attributes make FRP an ideal solution for molded dies used in manufacturing processes.

Advantages of FRP Molded Dies in Manufacturing

FRP molded dies present numerous advantages that can significantly improve efficiency and output in manufacturing operations. Below, we explore these benefits in detail.

1. Exceptional Durability

One of the standout features of FRP molded dies is their **exceptional durability**. Unlike traditional metal dies, which can deteriorate over time due to wear and tear, FRP dies maintain their structural integrity under extreme conditions. They are less prone to cracking, chipping, or warping, ensuring consistent performance over prolonged periods. This durability translates into reduced downtime for maintenance and replacement, allowing manufacturers to optimize productivity.

2. Cost-Effectiveness

Investing in FRP molded dies can lead to **significant cost savings** for manufacturers. While initial costs may be comparable to traditional dies, the longevity and reduced maintenance requirements of FRP translate into lower overall expenses. Additionally, the lightweight nature of FRP allows for easier handling and transportation, which can further reduce labor costs and logistical expenses.

3. Lightweight and Easy Handling

FRP molded dies are significantly lighter than their metal counterparts, making them easier to install, reposition, and maintain. This **lightweight characteristic** not only enhances handling efficiency but also reduces the risk of injury during installation and operation. With reduced weight, manufacturers can streamline their processes and improve ergonomics in the workplace.

4. Versatility in Applications

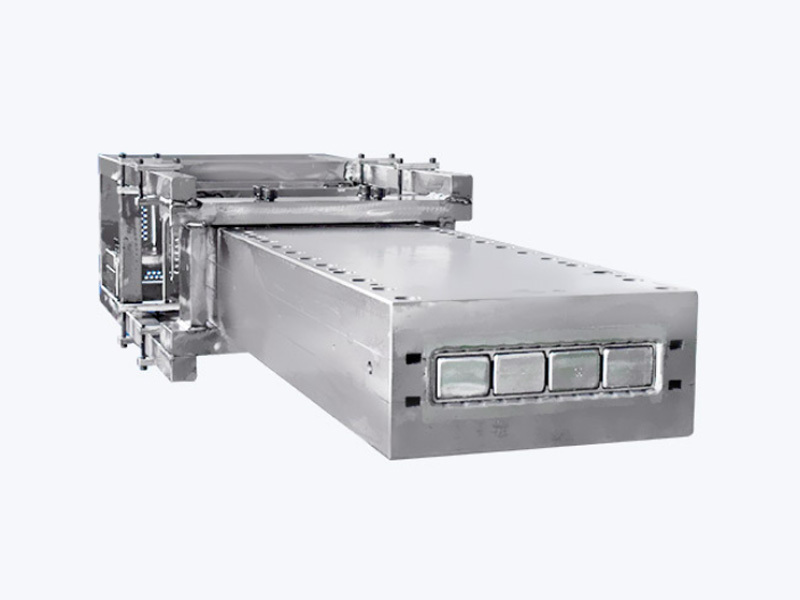

The versatility of **FRP molded dies** opens doors to a wide array of applications across different industries. From automotive and aerospace to consumer goods and electronics, FRP can be molded into complex shapes and sizes, catering to specific design requirements. This adaptability allows manufacturers to innovate and produce diverse products without the need for extensive tooling changes.

5. Corrosion Resistance

FRP molded dies exhibit excellent **corrosion resistance**, making them suitable for environments where traditional metal dies would succumb to rust and degradation. This property ensures that products manufactured with FRP dies maintain high quality and integrity over time, even when exposed to moisture or harsh chemicals. This resilience is particularly beneficial in industries such as food processing, pharmaceuticals, and chemical manufacturing.

Applications of FRP Molded Dies in Various Industries

The applications of FRP molded dies are vast, and their advantages make them a suitable choice for numerous industries. Some key applications include:

A. Automotive Industry

In the automotive sector, FRP molded dies are utilized for producing lightweight vehicle components that enhance fuel efficiency without compromising safety. Components such as body panels, bumpers, and interior elements benefit from the strength and durability of FRP, contributing to the overall performance of vehicles.

B. Aerospace Industry

The aerospace industry demands materials that offer high strength while being lightweight. FRP molded dies are employed in manufacturing components for aircraft, including wing structures and fuselage parts, adhering to strict safety and performance standards.

C. Consumer Goods

In consumer goods manufacturing, FRP molded dies are used for creating durable and appealing products. From household items to sporting goods, FRP enables the production of aesthetically pleasing and long-lasting products that meet consumer expectations.

D. Electronics

The electronics sector benefits from FRP molded dies in the production of housings and enclosures that require both strength and thermal stability. The lightweight nature of FRP also aids in the design of portable electronic devices, making it a popular choice among manufacturers.

Best Practices for Implementing FRP Molded Dies

To fully harness the advantages of FRP molded dies, manufacturers should adhere to best practices during the implementation process. Some key recommendations include:

A. Material Selection

Choosing the right type of FRP for specific applications is critical. Consider factors such as strength, thermal properties, and chemical resistance when selecting materials to ensure optimal performance.

B. Proper Maintenance

While FRP molded dies require less maintenance than traditional dies, regular inspections and cleaning should be implemented to prolong lifespan and maintain quality.

C. Training Personnel

Educating employees about the unique properties and handling of FRP materials can minimize accidents and improve operational efficiency. Training programs should focus on safe handling practices and maintenance procedures.

The Future of FRP Molded Dies in Manufacturing

As the manufacturing industry continues to evolve, the role of **FRP molded dies** is expected to grow. Advances in material science are paving the way for even more innovative applications, potentially leading to the development of new composites that enhance performance and sustainability. Additionally, as manufacturers seek to reduce their environmental footprint, FRP’s lightweight and recyclable properties will become increasingly valuable.

Frequently Asked Questions

1. What are the primary benefits of using FRP molded dies over metal dies?

FRP molded dies offer superior durability, corrosion resistance, lightweight characteristics, and cost-effectiveness compared to traditional metal dies.

2. Can FRP molded dies be used for high-temperature applications?

Yes, depending on the specific type of FRP material used, some FRP molded dies can withstand high temperatures, making them suitable for specific applications in industries such as aerospace.

3. How do FRP molded dies affect production efficiency?

The durability and lightweight nature of FRP molded dies lead to reduced downtime for maintenance, quicker handling, and the ability to produce complex shapes, all of which enhance production efficiency.

4. Are FRP molded dies environmentally friendly?

Yes, many FRP materials can be recycled, and their lightweight nature contributes to energy efficiency in manufacturing processes.

5. What industries can benefit from FRP molded dies?

Industries such as automotive, aerospace, consumer goods, and electronics can all benefit from the unique properties of FRP molded dies.

Conclusion

In conclusion, the adoption of **Fiber-Reinforced Plastic molded dies** is transforming the modern manufacturing landscape. With advantages such as exceptional durability, cost-effectiveness, lightweight characteristics, and versatility, FRP molded dies are becoming a preferred choice for diverse industrial applications. By strategically implementing FRP technologies, manufacturers can enhance efficiency, reduce costs, and drive innovation. As the future unfolds, FRP will likely continue to play a pivotal role in shaping the manufacturing sector, making it essential for businesses to embrace this technology for sustainable growth and competitive advantage.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.