Fast delivery

Global supplier

Innovative solutions

Innovative Applications of Pultruded Fiberglass Profiles in Building Design: A Comprehensive Guide

Jun 23,2025

Innovative Applications of Pultruded Fiberglass Profiles in Building Design

Table of Contents

- 1. Introduction to Pultruded Fiberglass Profiles

- 2. What is Pultrusion?

- 3. Benefits of Using Pultruded Fiberglass Profiles

- 4. Applications in Building Design

- 4.1 Structural Components

- 4.2 Facade Systems

- 4.3 Interior Design Elements

- 4.4 Green Building Applications

- 5. Case Studies: Successful Implementations

- 6. The Future of Pultruded Fiberglass in Construction

- 7. Challenges and Considerations

- 8. FAQs about Pultruded Fiberglass Profiles

- 9. Conclusion

1. Introduction to Pultruded Fiberglass Profiles

In the ever-evolving landscape of building materials, **pultruded fiberglass profiles** stand out for their remarkable properties and innovative applications. As architects and designers push the boundaries of creativity, pultruded fiberglass offers a versatile and sustainable solution, enabling the creation of aesthetically pleasing and highly functional structures. This article explores the diverse applications of pultruded fiberglass profiles in building design, showcasing their benefits, use cases, and potential challenges.

2. What is Pultrusion?

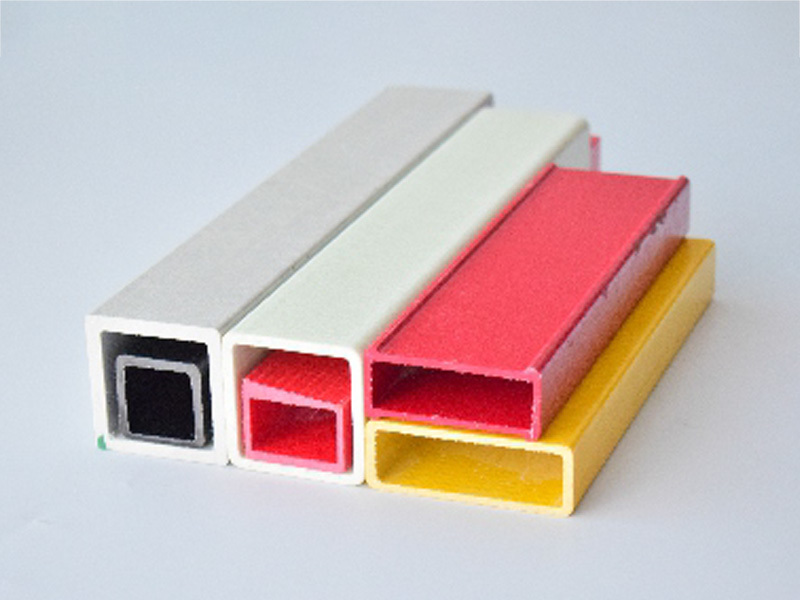

Pultrusion is a manufacturing process used to create composite materials, specifically **fiberglass-reinforced plastics**. This process involves drawing continuous fibers through a resin bath and then through a heated die, resulting in a cured and rigid profile. The resulting pultruded fiberglass profiles exhibit exceptional strength-to-weight ratios, corrosion resistance, and thermal insulation properties.

The **pultrusion process** allows for the production of custom shapes, sizes, and lengths, making it an ideal choice for various building applications. Its continuous production capability ensures consistency and efficiency, leading to cost-effective solutions for construction projects.

3. Benefits of Using Pultruded Fiberglass Profiles

The advantages of using **pultruded fiberglass profiles** in building design are manifold:

3.1 Lightweight and Strong

Pultruded fiberglass profiles possess a high strength-to-weight ratio, making them easier to handle and install than traditional materials like steel or wood. This lightweight nature reduces transportation costs and simplifies construction logistics.

3.2 Corrosion Resistance

Fiberglass profiles are inherently resistant to environmental factors such as moisture, chemicals, and UV radiation. This property ensures longevity and durability, particularly in harsh environments or coastal areas.

3.3 Thermal Insulation

The thermal insulating properties of pultruded fiberglass profiles contribute to energy efficiency in buildings. By minimizing heat transfer, they help maintain comfortable indoor temperatures and lower energy costs.

3.4 Design Flexibility

The customizable nature of pultruded fiberglass allows architects to experiment with innovative designs and unique shapes. This flexibility enables the creation of visually striking structures that stand out in the architectural landscape.

3.5 Sustainability

Pultruded fiberglass is often made from recycled materials and is fully recyclable at the end of its life cycle. Its energy-efficient production process further enhances its sustainability profile, making it an attractive option for green building projects.

4. Applications in Building Design

Pultruded fiberglass profiles find extensive applications in various aspects of building design, ranging from structural components to aesthetic features.

4.1 Structural Components

Pultruded fiberglass profiles are increasingly used in structural applications, including beams, columns, and trusses. Their lightweight nature and high strength make them suitable for load-bearing elements while reducing the overall weight of the structure. This can lead to savings in foundation costs and allow for more innovative building designs.

4.2 Facade Systems

In facade applications, pultruded fiberglass profiles can be used for cladding systems, window frames, and curtain walls. Their resistance to weathering and corrosion ensures that the facade maintains its aesthetic appeal over time, while their design flexibility allows for a range of architectural styles.

4.3 Interior Design Elements

In addition to structural uses, pultruded fiberglass profiles can enhance interior design. They can be employed in the creation of custom furniture, decorative wall panels, and unique lighting fixtures, contributing to a modern and innovative interior aesthetic.

4.4 Green Building Applications

With the increasing focus on sustainability in construction, pultruded fiberglass profiles are gaining traction in **green building** initiatives. Their energy-efficient properties, combined with the ability to produce sustainable designs, make them a favored choice for eco-friendly projects. Additionally, their light weight helps reduce the carbon footprint associated with transportation and installation.

5. Case Studies: Successful Implementations

Numerous projects have successfully utilized pultruded fiberglass profiles, showcasing their versatility and effectiveness in building design.

5.1 Coastal Residential Projects

In coastal areas, where materials are often subject to harsh conditions, builders have turned to pultruded fiberglass for decks, walkways, and railing systems. These profiles withstand saltwater corrosion and UV radiation, ensuring minimal maintenance and long-lasting performance.

5.2 Commercial Structures

Several commercial buildings have incorporated pultruded fiberglass in their facades, providing a unique visual appeal while maintaining durability. One notable example is an office building that utilized custom fiberglass profiles for its curtain wall system, demonstrating both aesthetic value and functional resilience.

6. The Future of Pultruded Fiberglass in Construction

As advancements in manufacturing techniques and material science continue to evolve, the future of pultruded fiberglass in construction looks promising. Innovations such as improved resin formulations and enhanced composite materials may lead to even greater strength, durability, and sustainability.

Architects and builders are likely to explore new avenues for utilizing pultruded fiberglass, from complex architectural forms to energy-efficient systems. As the demand for sustainable materials rises, pultruded fiberglass profiles will play a crucial role in shaping the future of building design.

7. Challenges and Considerations

While pultruded fiberglass profiles offer numerous advantages, some challenges and considerations must be addressed:

7.1 Cost

The initial cost of pultruded fiberglass profiles can be higher than traditional materials. However, the long-term savings in maintenance and durability often outweigh these initial expenditures.

7.2 Limited Awareness

Despite their benefits, there is still a limited awareness of pultruded fiberglass profiles within the construction industry. Increased education and outreach are necessary to promote their advantages and applications.

7.3 Installation Expertise

Working with pultruded fiberglass profiles requires specialized knowledge and skills. Ensuring that engineers and contractors are adequately trained in handling and installing these materials is essential for successful projects.

8. FAQs about Pultruded Fiberglass Profiles

What are pultruded fiberglass profiles made of?

Pultruded fiberglass profiles are made from continuous glass fibers impregnated with a resin, which is then cured through a heated die.

What are the advantages of using fiberglass over steel?

Fiberglass is lighter than steel, resistant to corrosion, and offers better thermal insulation. It can also be customized into various shapes and sizes.

How do pultruded fiberglass profiles compare to other composites?

Pultruded fiberglass profiles exhibit superior strength, lightweight properties, and resistance to environmental factors, making them ideal for structural applications.

Can pultruded fiberglass profiles be recycled?

Yes, pultruded fiberglass profiles can be fully recycled at the end of their life cycle, contributing to sustainability initiatives.

Are there specific building codes for using fiberglass in construction?

Yes, building codes vary by location, and it is essential to ensure that pultruded fiberglass profiles meet local regulations and standards for safety and performance.

9. Conclusion

Pultruded fiberglass profiles represent a significant advancement in building materials, offering an innovative and sustainable solution for modern architectural challenges. Their lightweight, durable, and corrosion-resistant properties make them an ideal choice for various applications, from structural components to aesthetic design features.

As the construction industry continues to evolve, the adoption of pultruded fiberglass profiles is likely to increase, paving the way for more creative and sustainable building designs. By embracing this material, architects and builders can take a step toward a greener future while enhancing the functionality and beauty of their projects.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.