Fast delivery

Global supplier

Innovative solutions

Understanding Discount FRP Molded Dies: A Comprehensive Guide for Manufacturers

Jul 10,2025

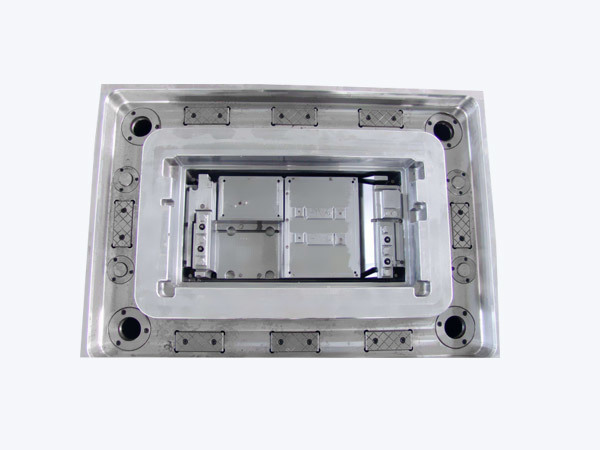

Discount FRP Molded Dies are increasingly gaining traction in the manufacturing sector, especially within the die casting and forging industries. FRP, or Fiber Reinforced Plastic, is a composite material known for its strength, lightweight properties, and corrosion resistance. When molded into dies, FRP presents a compelling option for manufacturers looking to reduce costs while maintaining quality and performance standards.

One of the primary benefits of using Discount FRP Molded Dies is their cost-effectiveness compared to traditional metal dies. Traditional dies, often made from steel or aluminum, can be expensive to produce and maintain. In contrast, FRP molds are typically less expensive to manufacture, allowing businesses to allocate resources more efficiently. This cost advantage is particularly appealing to small and medium-sized enterprises that may operate on tighter budgets.

Another significant advantage of FRP Molded Dies is their versatility. The material can be tailored to meet specific performance requirements, such as temperature resistance and chemical compatibility, making them suitable for a diverse range of applications. Whether producing intricate components for automotive parts or creating complex shapes in consumer goods, FRP molded dies can be customized to meet the exact needs of various industries.

Additionally, FRP molded dies boast faster production times. The lightweight nature of FRP allows for quicker mold handling, leading to shorter cycle times in manufacturing processes. This speed can translate to increased productivity, enabling manufacturers to meet higher demand without compromising quality.

However, potential users of Discount FRP Molded Dies should consider several factors before making a decision. The choice of resin and reinforcement materials significantly impacts the final product's properties. Manufacturers should assess their specific application requirements, including load-bearing capabilities and environmental conditions.

Moreover, while FRP molded dies can be highly durable, they may not be suitable for all applications, particularly those involving extreme pressures or high-volume production runs. Understanding the limitations and benefits of FRP will help manufacturers make informed choices that align with their operational goals.

In conclusion, Discount FRP Molded Dies represent an innovative solution for manufacturers looking to enhance their processes while managing costs. With their lightweight, cost-effective, and highly customizable features, FRP molded dies offer a practical alternative to traditional metal molds. By considering the unique attributes of these molded dies, manufacturers can improve their production efficiency and meet the evolving demands of the market. As the industry continues to advance, embracing materials like FRP will be essential for sustaining competitiveness and driving growth.

One of the primary benefits of using Discount FRP Molded Dies is their cost-effectiveness compared to traditional metal dies. Traditional dies, often made from steel or aluminum, can be expensive to produce and maintain. In contrast, FRP molds are typically less expensive to manufacture, allowing businesses to allocate resources more efficiently. This cost advantage is particularly appealing to small and medium-sized enterprises that may operate on tighter budgets.

Another significant advantage of FRP Molded Dies is their versatility. The material can be tailored to meet specific performance requirements, such as temperature resistance and chemical compatibility, making them suitable for a diverse range of applications. Whether producing intricate components for automotive parts or creating complex shapes in consumer goods, FRP molded dies can be customized to meet the exact needs of various industries.

Additionally, FRP molded dies boast faster production times. The lightweight nature of FRP allows for quicker mold handling, leading to shorter cycle times in manufacturing processes. This speed can translate to increased productivity, enabling manufacturers to meet higher demand without compromising quality.

However, potential users of Discount FRP Molded Dies should consider several factors before making a decision. The choice of resin and reinforcement materials significantly impacts the final product's properties. Manufacturers should assess their specific application requirements, including load-bearing capabilities and environmental conditions.

Moreover, while FRP molded dies can be highly durable, they may not be suitable for all applications, particularly those involving extreme pressures or high-volume production runs. Understanding the limitations and benefits of FRP will help manufacturers make informed choices that align with their operational goals.

In conclusion, Discount FRP Molded Dies represent an innovative solution for manufacturers looking to enhance their processes while managing costs. With their lightweight, cost-effective, and highly customizable features, FRP molded dies offer a practical alternative to traditional metal molds. By considering the unique attributes of these molded dies, manufacturers can improve their production efficiency and meet the evolving demands of the market. As the industry continues to advance, embracing materials like FRP will be essential for sustaining competitiveness and driving growth.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.