Fast delivery

Global supplier

Innovative solutions

Why Choose FRP Pultrusion Dies for Your Next Project? Discover the Advantages and Benefits

Feb 16,2026

Why Choose FRP Pultrusion Dies for Your Next Project?

Understanding FRP Pultrusion and Its Applications

FRP (Fiber Reinforced Polymer) pultrusion is a manufacturing process that creates continuous lengths of composite materials with high strength-to-weight ratios. Used widely across various industries, including aerospace, automotive, construction, and marine applications, FRP pultrusion involves drawing fibers through a resin bath and then through a heated die to produce solid, uniform profiles.

The versatility of FRP materials makes them suitable for applications ranging from structural components to decorative elements. As such, selecting the right pultrusion die is critical for ensuring that your final product meets all performance and aesthetic requirements.

What Are FRP Pultrusion Dies?

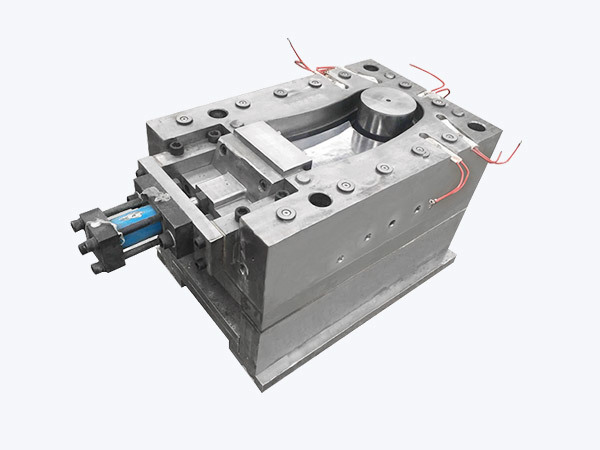

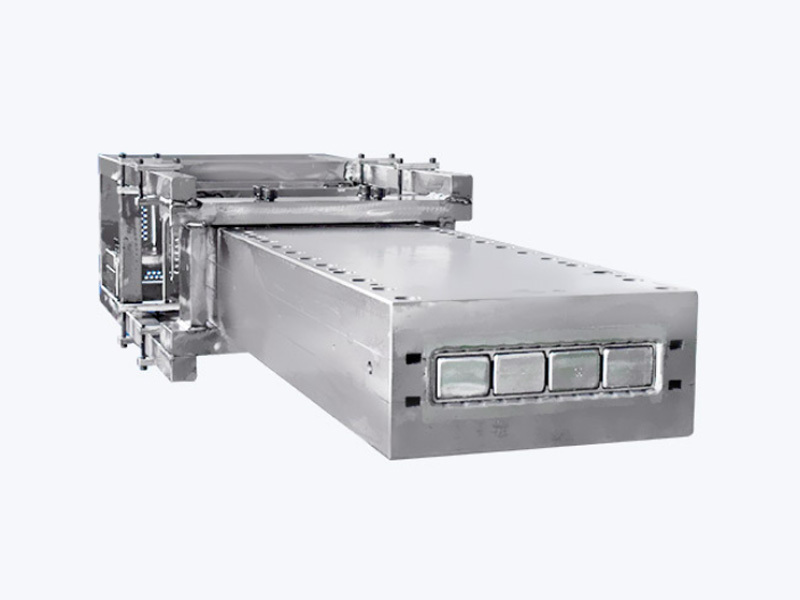

FRP pultrusion dies are specialized molds designed to shape the continuous profiles created in the pultrusion process. These dies are typically made from high-performance materials capable of withstanding the heat and pressure produced during the manufacturing cycle.

The innovation in die technology has led to two primary types of pultrusion dies:

1. Heated Dies

Heated dies are designed to maintain optimal temperatures for the curing process. This allows for faster production times and improved material consolidation, resulting in higher-quality finished products.

2. Non-Heated Dies

Non-heated dies are typically more cost-effective and are suitable for specific applications where lower temperatures are sufficient. While the production rate might be slower compared to heated dies, they still provide good quality outputs depending on the application.

The Advantages of Using FRP Pultrusion Dies

When considering materials for your next project, FRP pultrusion dies offer a plethora of benefits. Here are some key advantages to keep in mind:

1. Enhanced Material Properties

One of the standout benefits of using FRP is its exceptional strength and lightweight characteristics. The pultrusion process allows for tailored fiber orientations, which can significantly enhance the mechanical properties of the final product.

2. Cost Efficiency in Production

FRP pultrusion dies contribute to lower production costs through optimized manufacturing processes. The continuous nature of pultrusion minimizes waste and maximizes material usage, allowing manufacturers to save on raw materials.

3. Customization and Flexibility

FRP pultrusion dies can be designed to create a wide variety of shapes and sizes, making them highly adaptable to different project requirements. This level of customization enables manufacturers to develop unique solutions tailored to their specific needs.

4. Resistance to Corrosion and Environmental Factors

FRP materials are inherently resistant to corrosion, chemicals, and UV exposure, making them ideal for harsh environments. Using FRP pultrusion dies ensures that the end products can withstand various environmental challenges without compromising performance.

5. Sustainability and Environmental Impact

With increasing awareness of environmental issues, using FRP pultrusion dies aligns with sustainable manufacturing practices. FRP materials can be fabricated with recyclable components, and the process itself produces less waste compared to traditional materials.

Choosing the Right FRP Pultrusion Die for Your Project

Selecting the right FRP pultrusion die is essential for the success of your project. Here are some considerations to guide your decision-making process:

1. Determine the Desired Profile

The first step in choosing a die is to clearly define the desired profile shape and dimensions. Whether you need simple shapes or complex geometries, identifying your needs upfront will help you communicate effectively with die manufacturers.

2. Material Compatibility

Ensure that the die material is suitable for the type of resin and fibers you plan to use. Different combinations may require specific die materials to achieve optimal performance and durability.

3. Heat Requirements

Evaluate whether your project necessitates a heated or non-heated die. Heated dies can enhance curing times and improve material properties, while non-heated dies may save on initial investments.

4. Production Volume and Speed

Consider the volume and speed requirements of your production. If you anticipate high production rates, investing in advanced die technology may yield better long-term returns.

5. Budget Constraints

Lastly, assess your budget for die procurement. While it's essential to consider costs, remember that investing in high-quality dies can lead to significant savings in production inefficiencies and material waste.

Maintaining and Caring for FRP Pultrusion Dies

Proper maintenance of FRP pultrusion dies is critical for ensuring longevity and optimal performance. Here are some best practices to follow:

1. Regular Cleaning

After each production run, clean the dies thoroughly to remove any residue or build-up. Use appropriate cleaning agents that will not damage the die material.

2. Inspections

Conduct regular inspections to identify wear and tear. Early detection of issues can prevent costly repairs and extend the life of the die.

3. Storage Conditions

Store dies in a clean, dry environment when not in use. Proper storage minimizes exposure to elements that could cause deterioration.

Common Applications of FRP Pultrusion Dies

FRP pultrusion dies are employed in various industries due to their versatility. Here are some common applications:

1. Architectural Elements

In construction and architecture, FRP pultrusion is used to produce columns, beams, and decorative elements that require both strength and aesthetic appeal.

2. Electrical and Power Transmission

FRP materials are ideal for insulators, cross-arms, and other components in the electrical industry due to their excellent electrical insulating properties and resistance to corrosion.

3. Transportation Components

In the automotive and aerospace sectors, FRP pultrusion produces lightweight, durable components, contributing to fuel efficiency and performance.

4. Water and Waste Management

FRP pultrusion is increasingly used for tanks, pipes, and structural supports in water and wastewater management due to its corrosion resistance and longevity.

Future Trends in FRP Pultrusion Technology

As technology advances, several trends are emerging in the field of FRP pultrusion:

1. Integration of Smart Technologies

The incorporation of smart technologies, such as IoT sensors, in pultrusion processes will enable real-time monitoring and optimization of production cycles.

2. Sustainability Initiatives

With a growing focus on sustainability, manufacturers are increasingly seeking eco-friendly resins and fibers, paving the way for greener pultrusion processes.

3. Advanced Automation

Automation in the pultrusion process is set to improve efficiency and reduce labor costs, enabling manufacturers to scale production without compromising quality.

FAQs About FRP Pultrusion Dies

1. What are the main benefits of using FRP pultrusion dies?

The main benefits include enhanced material properties, cost efficiency, customization, resistance to environmental factors, and sustainability.

2. How do I know if I need a heated or non-heated die?

Consider the resin type and curing requirements. Heated dies are suitable for faster production and improved material properties.

3. Can FRP pultrusion dies be reused?

Yes, with proper maintenance and care, FRP pultrusion dies can be reused for multiple production runs.

4. What industries benefit most from FRP pultrusion?

Industries such as construction, transportation, aerospace, and electrical applications significantly benefit from FRP pultrusion technology.

5. Are there any limitations to using FRP materials?

While FRP materials offer many advantages, they may have lower impact resistance compared to metals and can be more expensive for certain applications.

Conclusion

In summary, choosing FRP pultrusion dies for your next project can provide numerous advantages, including enhanced material properties, cost efficiency, and customization. As the demand for high-performance materials continues to grow across various industries, understanding the benefits and applications of FRP pultrusion dies will empower manufacturers to make informed decisions that will ultimately lead to successful project outcomes. By investing in the right technology and maintaining your dies properly, you can ensure a seamless production process while achieving superior final products that meet both functional and aesthetic requirements.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.