Fast delivery

Global supplier

Innovative solutions

How to Align Your Business Goals with FRP Pultrusion Die Capabilities

Jun 05,2025

Understanding the Importance of FRP Pultrusion in Manufacturing

FRP (Fiber Reinforced Polymer) pultrusion is a manufacturing process that produces continuous lengths of composite materials, offering unparalleled strength-to-weight ratios. For businesses aiming to enhance their production capabilities, understanding how to align business goals with FRP pultrusion die capabilities is crucial. In this article, we will explore the various aspects of FRP pultrusion, its benefits, and how you can strategically align your manufacturing goals with the capabilities of pultrusion dies.

Table of Contents

- Understanding FRP Pultrusion

- Benefits of FRP Pultrusion Dies

- Customizing Dies for Business Needs

- Aligning Business Goals with Die Capabilities

- Maximizing Efficiency Through Die Optimization

- Case Studies in FRP Pultrusion

- Future Trends in FRP Pultrusion

- Frequently Asked Questions

Understanding FRP Pultrusion

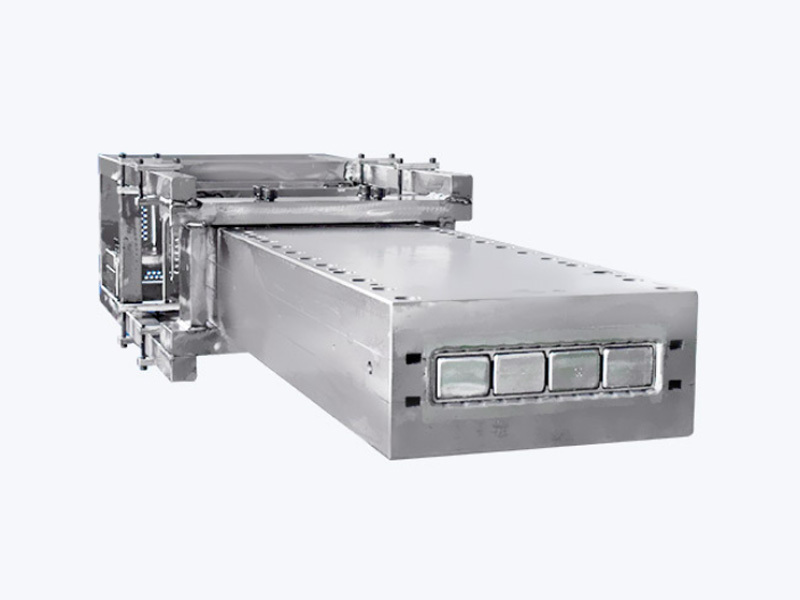

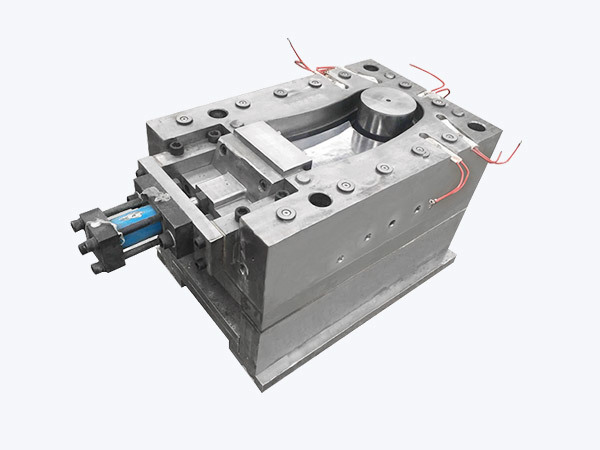

FRP pultrusion is a process that involves the continuous pulling of resin-impregnated fibers through a heated die, resulting in a cured composite material. This method is notable for creating strong, lightweight products with excellent corrosion resistance, making it ideal for various applications, including construction, automotive, and aerospace industries.

The **key components** of the pultrusion process include:

- **Raw Materials**: Fibers such as glass, carbon, or aramid, combined with thermosetting resins.

- **Die Design**: Custom-made dies that shape and cure the composite as it is pulled through.

- **Curing Process**: The application of heat within the die to ensure the material hardens properly.

Benefits of FRP Pultrusion Dies

Investing in high-quality FRP pultrusion dies can yield significant advantages for manufacturers. The benefits include:

1. Enhanced Product Quality

High-quality dies ensure precise control over the dimensions and material properties of the finished products, leading to consistent quality.

2. Increased Production Efficiency

Optimally designed dies facilitate a smoother pultrusion process, thereby reducing cycle times and increasing throughput.

3. Cost-Effectiveness

By minimizing waste and maximizing the use of raw materials, efficient dies contribute to overall cost savings in production.

4. Versatility in Applications

Customizable die designs allow manufacturers to create a wide range of products tailored to specific market needs.

Customizing Dies for Business Needs

To truly harness the potential of FRP pultrusion, businesses must invest in customized dies that meet their specific manufacturing requirements. This section explores how to tailor dies effectively.

1. Assessing Material Needs

Start by understanding the specific fibers and resins that are suited for your end products. Different materials may require unique die designs for optimal performance.

2. Collaborating with Die Manufacturers

Work closely with die manufacturers to design dies that meet both your technical specifications and production goals. Communication is key to achieving the desired results.

3. Iterative Design Process

Utilize an iterative design approach, where prototypes of the die are tested and refined based on performance feedback. This can lead to better efficiency and product quality.

Aligning Business Goals with Die Capabilities

Aligning your business goals with the capabilities of FRP pultrusion dies can provide a clear competitive advantage. Here are steps to ensure alignment:

1. Define Your Business Objectives

Identify the primary goals of your business, whether it's expanding market share, increasing production speed, or reducing costs.

2. Evaluate Current Die Capabilities

Conduct a thorough assessment of your existing die capabilities. Are they meeting your business objectives? If not, identify the gaps.

3. Invest in Innovative Die Technologies

Consider investing in the latest die technologies that can help you achieve your business objectives. Innovations such as automated die systems or advanced cooling technologies can enhance production capabilities.

4. Monitor Industry Trends

Stay informed about industry trends that can influence your business goals. This includes awareness of new materials, regulatory changes, and shifts in consumer demand.

Maximizing Efficiency Through Die Optimization

To achieve the desired alignment between business goals and die capabilities, optimizing the performance of your pultrusion dies is crucial. Here are strategies for effective die optimization:

1. Regular Maintenance and Upgrades

Routine maintenance of dies ensures they operate at peak efficiency. Upgrades should also be considered as technology advances.

2. Process Monitoring

Implement real-time monitoring systems to track die performance metrics. This data can help identify potential issues before they escalate.

3. Training and Skill Development

Invest in training your workforce to handle die operations effectively. A well-trained team can significantly improve production outcomes.

Case Studies in FRP Pultrusion

Examining successful case studies in FRP pultrusion can provide valuable insights into how different businesses have aligned their goals with die capabilities:

1. Case Study: Construction Industry

A leading construction firm optimized its FRP pultrusion process by investing in customized dies, resulting in a 30% increase in production efficiency.

2. Case Study: Automotive Sector

An automotive manufacturer leveraged advanced die technologies to reduce material waste by 20%, aligning with their sustainability goals.

Future Trends in FRP Pultrusion

As the manufacturing landscape continues to evolve, several trends are shaping the future of FRP pultrusion:

1. Sustainable Manufacturing Practices

An increasing focus on sustainability is driving innovations in the materials and processes used for FRP pultrusion.

2. Automation

The integration of automation technologies in the pultrusion process is streamlining operations and enhancing productivity.

3. Advanced Materials

The development of new composite materials is expanding the applications of FRP pultrusion, making it an attractive option for various industries.

Frequently Asked Questions

1. What is FRP pultrusion?

FRP pultrusion is a manufacturing process that creates continuous lengths of composite materials by pulling resin-impregnated fibers through a heated die.

2. What are the advantages of using FRP pultrusion?

Advantages include enhanced product quality, increased production efficiency, cost-effectiveness, and versatility in applications.

3. How can dies be customized for specific needs?

Dies can be customized by assessing material requirements, collaborating with manufacturers, and using an iterative design process.

4. What should I consider when aligning business goals with die capabilities?

Consider defining your business objectives, evaluating current die capabilities, investing in innovative technologies, and monitoring industry trends.

5. What future trends should I be aware of in FRP pultrusion?

Key trends include sustainable manufacturing practices, automation, and the development of advanced materials.

Conclusion

Aligning your business goals with the capabilities of FRP pultrusion dies is essential for maximizing efficiency, enhancing product quality, and achieving competitive advantages in the manufacturing industry. By understanding the benefits of pultrusion, customizing your die solutions, and continuously optimizing their performance, you can ensure that your business remains at the forefront of innovation. The future of FRP pultrusion is promising, and with strategic alignment, your company can thrive in an ever-evolving marketplace.

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.