Fast delivery

Global supplier

Innovative solutions

Understanding Cementing Boxes: Key Considerations for Manufacturing Professionals in Molds and Die Casting

Jun 06,2025

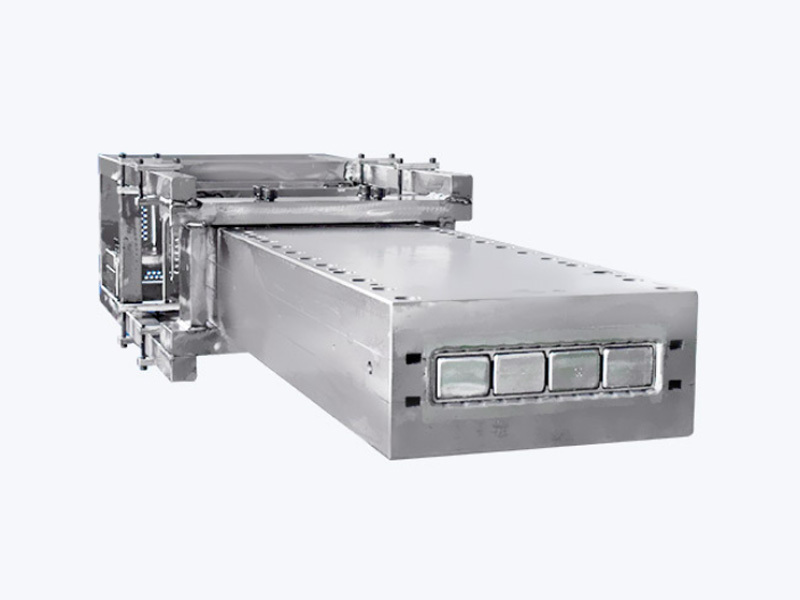

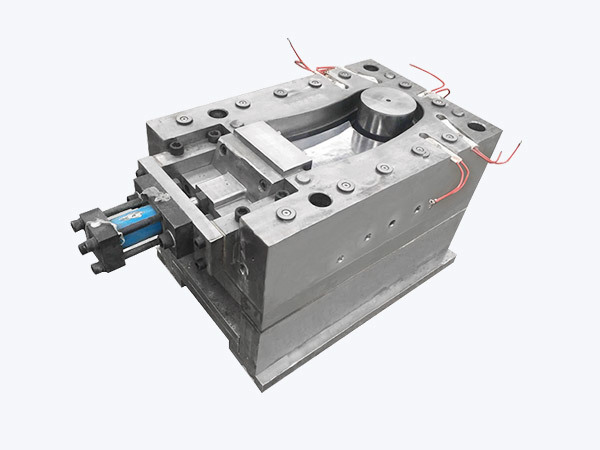

Cementing boxes are essential components in various manufacturing processes, particularly within the mold and die casting sector. Their primary function is to ensure the secure assembly of different parts, particularly in creating molds that can withstand the pressures of molten materials during casting processes. Understanding the intricacies of cementing boxes can significantly benefit manufacturing professionals aiming to optimize their production capabilities.

One of the primary considerations when selecting cementing boxes is the material used in their construction. The material needs to possess high strength, durability, and resistance to temperature fluctuations, as molds and dies are often subjected to extreme conditions during operation. Furthermore, the thermal conductivity of the cementing box material can impact heat distribution, which is critical for achieving uniform mold temperatures and preventing defects in the final casting products.

Another important aspect is the design of the cementing box itself. The box must be engineered to accommodate the specific dimensions and shapes of the components it will hold. This often involves considerations related to tolerances and clearances, which are vital for ensuring that the assembled mold functions properly and yields high-quality castings. Utilizing computer-aided design (CAD) software can significantly aid in creating precise molds and cementing boxes that meet stringent industry standards.

Additionally, the application process of the cementing material within the box is essential for achieving optimal performance. Proper mixing and curing techniques must be employed to ensure the strength and integrity of the bonds formed within the box. Manufacturing professionals should pay attention to factors such as humidity, temperature, and mixing ratios, as these can adversely affect the final product if not meticulously controlled.

Moreover, regular maintenance and quality checks of cementing boxes are crucial to sustain their functionality over time. Implementing a routine inspection schedule can help identify wear and tear early, preventing costly downtime and ensuring continuous production flow.

In conclusion, cementing boxes are integral to the mold-making and die casting processes in the manufacturing sector. By understanding the materials, designs, application processes, and maintenance practices associated with cementing boxes, professionals can enhance their operations, leading to improved product quality and efficiency. Staying informed about advancements in cementing technologies and materials is also vital for maintaining a competitive edge in the industry. Embracing these insights will empower manufacturing professionals to make informed decisions that positively impact their production capabilities.

One of the primary considerations when selecting cementing boxes is the material used in their construction. The material needs to possess high strength, durability, and resistance to temperature fluctuations, as molds and dies are often subjected to extreme conditions during operation. Furthermore, the thermal conductivity of the cementing box material can impact heat distribution, which is critical for achieving uniform mold temperatures and preventing defects in the final casting products.

Another important aspect is the design of the cementing box itself. The box must be engineered to accommodate the specific dimensions and shapes of the components it will hold. This often involves considerations related to tolerances and clearances, which are vital for ensuring that the assembled mold functions properly and yields high-quality castings. Utilizing computer-aided design (CAD) software can significantly aid in creating precise molds and cementing boxes that meet stringent industry standards.

Additionally, the application process of the cementing material within the box is essential for achieving optimal performance. Proper mixing and curing techniques must be employed to ensure the strength and integrity of the bonds formed within the box. Manufacturing professionals should pay attention to factors such as humidity, temperature, and mixing ratios, as these can adversely affect the final product if not meticulously controlled.

Moreover, regular maintenance and quality checks of cementing boxes are crucial to sustain their functionality over time. Implementing a routine inspection schedule can help identify wear and tear early, preventing costly downtime and ensuring continuous production flow.

In conclusion, cementing boxes are integral to the mold-making and die casting processes in the manufacturing sector. By understanding the materials, designs, application processes, and maintenance practices associated with cementing boxes, professionals can enhance their operations, leading to improved product quality and efficiency. Staying informed about advancements in cementing technologies and materials is also vital for maintaining a competitive edge in the industry. Embracing these insights will empower manufacturing professionals to make informed decisions that positively impact their production capabilities.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.