Fast delivery

Global supplier

Innovative solutions

Unlocking the Benefits of Polyurethane Pultrusion Dies in Manufacturing

Jun 07,2025

Unlocking the Benefits of Polyurethane Pultrusion Dies in Manufacturing

In the ever-evolving landscape of manufacturing, companies constantly seek innovative solutions that enhance efficiency, reduce costs, and improve product quality. One such solution making waves in the industry is **polyurethane pultrusion dies**. These specialized tools are transforming the way products are manufactured, offering a range of benefits that traditional materials cannot match. In this article, we delve into the world of polyurethane pultrusion dies, exploring their advantages, applications, and the future of manufacturing.

Understanding Polyurethane Pultrusion Dies

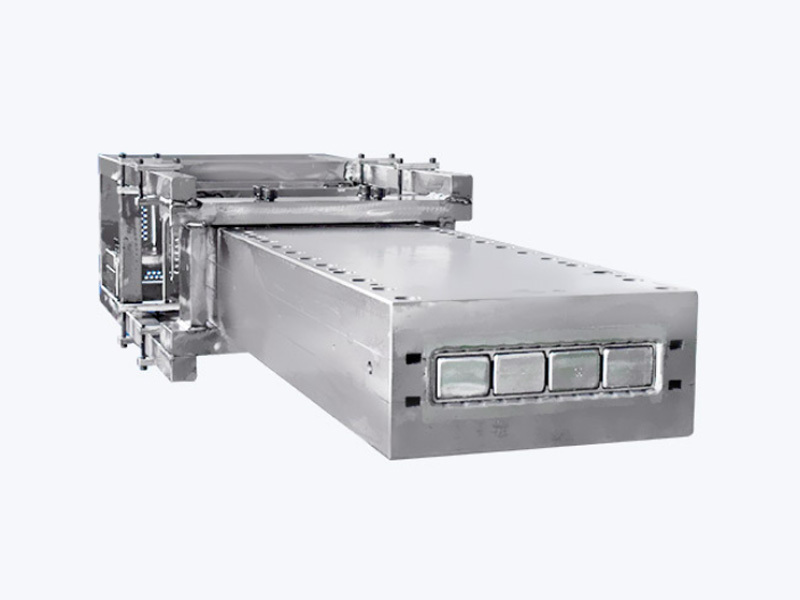

Polyurethane pultrusion dies are made from polyurethane elastomers, which are known for their exceptional durability and versatility. Pultrusion is a manufacturing process where continuous fibers are pulled through a resin bath and then through a heated die to create a composite material. The use of polyurethane in this process results in dies that are not only robust but also capable of producing high-quality, dimensionally stable parts.

The Composition of Polyurethane and Its Benefits

Polyurethane is a polymer composed of organic units joined by carbamate (urethane) links. This composition grants it several advantageous properties:

- **High tensile strength**: Polyurethane is strong and can withstand significant stress without deforming.

- **Flexibility**: The material can be formulated to achieve varying degrees of flexibility, making it suitable for a wide range of applications.

- **Chemical resistance**: Polyurethane resists various chemicals, ensuring longevity and reliability in harsh manufacturing environments.

- **Lightweight**: Compared to metals, polyurethane provides a lighter alternative, reducing transportation costs and energy consumption during manufacturing.

The Advantages of Using Polyurethane Pultrusion Dies

As industries look for ways to optimize their manufacturing processes, polyurethane pultrusion dies have emerged as a game-changer. Below are some key benefits that make these dies a preferred choice.

1. Enhanced Durability and Longevity

Polyurethane dies are known for their exceptional durability. They withstand wear and tear better than traditional metal dies, reducing the frequency of replacements and maintenance. This durability translates into cost savings over time, as manufacturers can allocate resources more effectively.

2. Superior Surface Finish

The smooth surface of polyurethane dies allows for a high-quality finish on the products manufactured. This superior surface quality reduces the need for additional finishing processes, thereby saving time and resources during production.

3. Design Flexibility

Polyurethane pultrusion dies can be easily customized to achieve specific shapes and designs. This adaptability allows manufacturers to experiment with complex geometries and intricate designs without incurring significant costs or delays.

4. Reduction in Production Time

The rapid heating and cooling capabilities of polyurethane dies facilitate faster production cycles. Manufacturers can produce components more efficiently, meeting market demands without compromising on quality.

5. Cost-Effectiveness

While the initial investment in polyurethane dies may be higher than traditional options, their longevity and reduced maintenance requirements lead to significant cost savings in the long run. Additionally, the efficiency gained through quicker production cycles further enhances overall cost-effectiveness.

Applications of Polyurethane Pultrusion Dies

The versatility of polyurethane pultrusion dies allows them to be utilized across various industries. Here are some key applications:

1. Automotive Industry

In the automotive sector, manufacturers use polyurethane pultrusion dies to produce lightweight and durable components. These components contribute to fuel efficiency and overall vehicle performance while maintaining safety standards.

2. Aerospace Industry

Polyurethane's lightweight nature and exceptional strength make it an ideal choice for aerospace applications. Dies manufactured from polyurethane can create complex parts that meet the stringent requirements of aerospace engineering.

3. Construction Industry

In construction, polyurethane pultrusion dies are used to fabricate components such as support beams, columns, and panels. These components offer high strength-to-weight ratios, making them ideal for modern architectural designs.

4. Electrical and Electronics

Polyurethane's insulating properties make it suitable for electrical components. Dies are used to produce housings and insulators that protect sensitive electronic parts from environmental factors.

5. Marine Industry

The marine industry benefits from polyurethane's resistance to corrosion and moisture. Pultrusion dies are utilized to create parts for boats and ships that can withstand harsh marine conditions.

Future Trends in Polyurethane Pultrusion Dies

As technology advances, the future of polyurethane pultrusion dies looks promising. Here are some trends to watch for:

1. Automation and Robotics

The integration of automation and robotics in the pultrusion process is expected to enhance production efficiency further. Automated systems can reduce human error and streamline operations.

2. Advanced Materials

The development of new polyurethane formulations will likely lead to even better performance characteristics. Manufacturers will continue to innovate, creating dies that can withstand higher temperatures and offer improved mechanical properties.

3. Sustainable Practices

The manufacturing industry is increasingly focusing on sustainability. Future polyurethane formulations may incorporate recycled materials, reducing environmental impact and promoting circular economy practices.

Challenges and Considerations

While the benefits are significant, there are challenges associated with implementing polyurethane pultrusion dies.

1. Initial Investment Costs

The upfront costs for polyurethane dies can be daunting for smaller manufacturers. However, the long-term savings and efficiency gains often justify this initial investment.

2. Technical Expertise

Operating and maintaining polyurethane pultrusion equipment requires specialized knowledge. Manufacturers should invest in training and resources to ensure optimal performance.

Frequently Asked Questions (FAQs)

1. What are polyurethane pultrusion dies?

Polyurethane pultrusion dies are specialized tools used in the pultrusion process to shape composite materials. They are made from durable polyurethane elastomers.

2. How do polyurethane dies compare to traditional metal dies?

Polyurethane dies offer better durability, flexibility, and surface finish compared to traditional metal dies. They also reduce production time and costs in the long run.

3. What industries benefit from polyurethane pultrusion dies?

Industries such as automotive, aerospace, construction, electrical, electronics, and marine have seen significant advantages from using polyurethane pultrusion dies.

4. Are polyurethane dies environmentally friendly?

While polyurethane itself is a synthetic material, there is a growing trend toward developing sustainable formulations that incorporate recycled materials, thus reducing environmental impact.

5. What is the expected lifespan of polyurethane pultrusion dies?

The lifespan of polyurethane dies can vary based on usage and maintenance, but they generally outlast traditional metal dies, offering significant long-term value.

Conclusion

Polyurethane pultrusion dies represent a remarkable advancement in manufacturing technology, providing numerous benefits that enhance efficiency, product quality, and overall cost-effectiveness. As industries evolve and demand for innovative solutions increases, the role of these advanced dies will become even more critical. By embracing the advantages of polyurethane pultrusion dies, manufacturers can not only improve their production processes but also position themselves at the forefront of industry innovation and sustainability. The future is bright for those willing to explore and invest in this transformative technology.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.