Fast delivery

Global supplier

Innovative solutions

Understanding GRP Structural Profiles: Advantages and Applications in Construction

Jun 24,2025

GRP, or Glass Reinforced Plastic, is a composite material that combines the lightweight properties of plastic with the strength and durability provided by glass fibers. GRP structural profiles are essential components in modern construction, offering a diverse range of benefits that make them suitable for various applications.

One of the most notable advantages of GRP structural profiles is their exceptional strength-to-weight ratio. This means that they can support significant loads while being much lighter than traditional materials like steel or concrete. As a result, architects and engineers often favor GRP for structural applications where reducing weight is crucial, such as in the design of rooftops, bridges, and facades.

Additionally, GRP materials exhibit excellent resistance to corrosion, chemicals, and environmental factors. This makes them ideal for use in harsh environments, including coastal areas where exposure to saltwater can deteriorate other building materials. With GRP structural profiles, the lifespan of a structure can be significantly enhanced, reducing maintenance costs and extending service life.

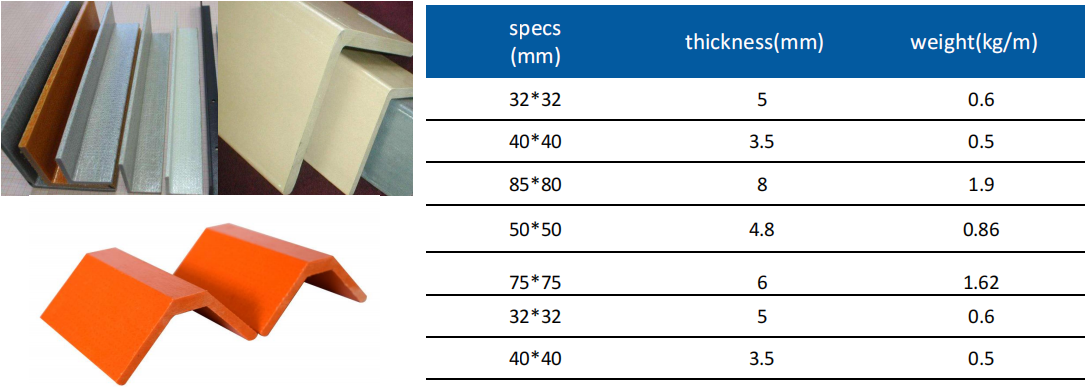

Another compelling feature of GRP is its versatility. The profiles can be manufactured in various shapes and sizes, accommodating specific design requirements. This adaptability allows architects and designers to create unique structures that can meet aesthetic and functional needs without compromising on performance.

Moreover, GRP is an energy-efficient material. The manufacturing processes for GRP profiles typically consume less energy compared to traditional construction materials. Additionally, their lightweight nature contributes to lower transportation costs and reduced carbon emissions, aligning with the growing emphasis on sustainability in the construction industry.

In terms of aesthetics, GRP structural profiles can be finished in various colors and textures, providing architects with the creative freedom to incorporate these materials into diverse design schemes. This flexibility not only enhances the visual appeal of a project but also allows it to blend seamlessly with surrounding structures.

Overall, GRP structural profiles are transforming the landscape of construction and decorative materials. With their unique combination of strength, lightweight properties, corrosion resistance, and design versatility, they offer a practical solution for modern architectural challenges. As the industry continues to evolve, the adoption of GRP materials is likely to increase, making them a crucial component in the quest for innovative and sustainable building solutions. Whether for residential, commercial, or industrial applications, GRP structural profiles represent a forward-thinking choice for contemporary construction needs.

One of the most notable advantages of GRP structural profiles is their exceptional strength-to-weight ratio. This means that they can support significant loads while being much lighter than traditional materials like steel or concrete. As a result, architects and engineers often favor GRP for structural applications where reducing weight is crucial, such as in the design of rooftops, bridges, and facades.

Additionally, GRP materials exhibit excellent resistance to corrosion, chemicals, and environmental factors. This makes them ideal for use in harsh environments, including coastal areas where exposure to saltwater can deteriorate other building materials. With GRP structural profiles, the lifespan of a structure can be significantly enhanced, reducing maintenance costs and extending service life.

Another compelling feature of GRP is its versatility. The profiles can be manufactured in various shapes and sizes, accommodating specific design requirements. This adaptability allows architects and designers to create unique structures that can meet aesthetic and functional needs without compromising on performance.

Moreover, GRP is an energy-efficient material. The manufacturing processes for GRP profiles typically consume less energy compared to traditional construction materials. Additionally, their lightweight nature contributes to lower transportation costs and reduced carbon emissions, aligning with the growing emphasis on sustainability in the construction industry.

In terms of aesthetics, GRP structural profiles can be finished in various colors and textures, providing architects with the creative freedom to incorporate these materials into diverse design schemes. This flexibility not only enhances the visual appeal of a project but also allows it to blend seamlessly with surrounding structures.

Overall, GRP structural profiles are transforming the landscape of construction and decorative materials. With their unique combination of strength, lightweight properties, corrosion resistance, and design versatility, they offer a practical solution for modern architectural challenges. As the industry continues to evolve, the adoption of GRP materials is likely to increase, making them a crucial component in the quest for innovative and sustainable building solutions. Whether for residential, commercial, or industrial applications, GRP structural profiles represent a forward-thinking choice for contemporary construction needs.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.