Fast delivery

Global supplier

Innovative solutions

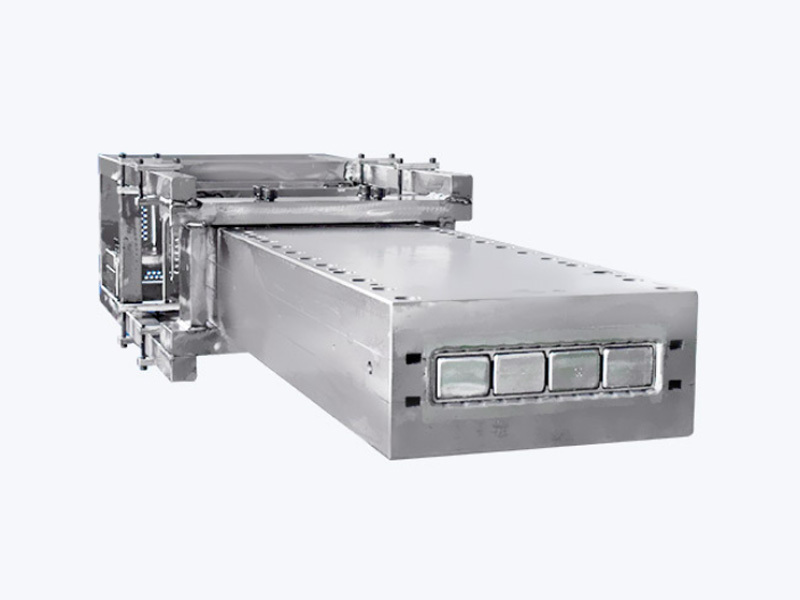

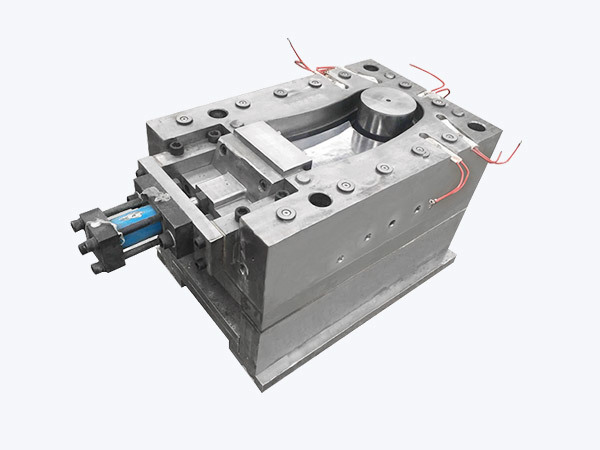

Understanding the Role of Cementing Boxes in Molding and Die-Casting Processes

Feb 19,2026

In the manufacturing sector, specifically in the realm of molding and die-casting, the term "cementing box" refers to a crucial component used for ensuring the integrity and precision of molds. These boxes are designed to hold and support molds during the casting process, which is vital for achieving the desired shape and quality of the final product. Understanding the role of cementing boxes can significantly impact manufacturing processes and outcomes.

Cementing boxes serve multiple purposes. First and foremost, they provide structural integrity. During the casting process, molten metal or other materials can exert considerable pressure. A well-designed cementing box ensures that the mold remains stable under these conditions, preventing any deformation that could lead to defects in the final product. This stability is essential in high-volume production environments where consistency and precision are paramount.

In addition to providing stability, cementing boxes also facilitate ease of use. They are often designed with features that allow for quick assembly and disassembly, which can be a significant advantage in fast-paced manufacturing settings. This ease of handling can reduce downtime between production runs and help maintain a continuous workflow, thus improving overall efficiency.

Another critical aspect of cementing boxes is their contribution to temperature control during the casting process. The materials used in these boxes can have insulating properties that help manage the temperature of the molten materials. This temperature regulation is vital to avoid issues like premature solidification or uneven cooling, which can compromise the quality of the cast product.

Moreover, the versatility of cementing boxes allows them to be adapted for various applications within the industry. Whether it’s for precision engineering, automotive components, or custom molds, the design and configuration of cementing boxes can be tailored to meet specific requirements. This adaptability ensures that manufacturers can achieve optimal results across different projects.

In summary, cementing boxes are a fundamental element in the manufacturing of molds and die-casting processes. Their ability to provide stability, facilitate ease of use, and contribute to temperature control makes them indispensable in ensuring high-quality production outcomes. Understanding their importance can lead to more informed decisions in the design and operation of manufacturing processes, ultimately driving efficiency and product excellence. As you consider your operations, integrating robust cementing box solutions could be a step towards optimizing your manufacturing capabilities.

Cementing boxes serve multiple purposes. First and foremost, they provide structural integrity. During the casting process, molten metal or other materials can exert considerable pressure. A well-designed cementing box ensures that the mold remains stable under these conditions, preventing any deformation that could lead to defects in the final product. This stability is essential in high-volume production environments where consistency and precision are paramount.

In addition to providing stability, cementing boxes also facilitate ease of use. They are often designed with features that allow for quick assembly and disassembly, which can be a significant advantage in fast-paced manufacturing settings. This ease of handling can reduce downtime between production runs and help maintain a continuous workflow, thus improving overall efficiency.

Another critical aspect of cementing boxes is their contribution to temperature control during the casting process. The materials used in these boxes can have insulating properties that help manage the temperature of the molten materials. This temperature regulation is vital to avoid issues like premature solidification or uneven cooling, which can compromise the quality of the cast product.

Moreover, the versatility of cementing boxes allows them to be adapted for various applications within the industry. Whether it’s for precision engineering, automotive components, or custom molds, the design and configuration of cementing boxes can be tailored to meet specific requirements. This adaptability ensures that manufacturers can achieve optimal results across different projects.

In summary, cementing boxes are a fundamental element in the manufacturing of molds and die-casting processes. Their ability to provide stability, facilitate ease of use, and contribute to temperature control makes them indispensable in ensuring high-quality production outcomes. Understanding their importance can lead to more informed decisions in the design and operation of manufacturing processes, ultimately driving efficiency and product excellence. As you consider your operations, integrating robust cementing box solutions could be a step towards optimizing your manufacturing capabilities.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.