Fast delivery

Global supplier

Innovative solutions

A Deep Dive into the Mechanics of Polyurethane Pultrusion Dies

Feb 22,2026

A Deep Dive into the Mechanics of Polyurethane Pultrusion Dies

In the manufacturing industry, the efficiency and effectiveness of production processes heavily depend on the tools and machinery used. Among these, polyurethane pultrusion dies have emerged as pivotal components in creating high-performance composite materials. This article will thoroughly explore the mechanics of polyurethane pultrusion dies, their design intricacies, operational principles, and their significance in various applications.

Table of Contents

- 1. Introduction to Polyurethane Pultrusion Dies

- 2. Understanding the Pultrusion Process

- 3. The Mechanics of Polyurethane Dies

- 4. Design and Engineering Considerations

- 5. Material Selection for Pultrusion Dies

- 6. Applications of Polyurethane Pultrusion Dies

- 7. Advantages of Using Polyurethane Dies

- 8. Future Trends in Pultrusion Technology

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Polyurethane Pultrusion Dies

Polyurethane pultrusion dies play a crucial role in the manufacturing of composite materials, particularly in industries such as automotive, aerospace, and construction. These dies facilitate the pultrusion process, which involves the continuous production of composite profiles by pulling resin-impregnated fibers through a heated die. Understanding the mechanics of these dies is essential for optimizing production efficiency and achieving desired material properties.

2. Understanding the Pultrusion Process

The pultrusion process is characterized by several key steps. Initially, fibers such as glass or carbon are pulled through a resin bath, where they are thoroughly impregnated with a thermosetting resin. This mixture is then drawn through a die that shapes the material into the desired profile. The heat applied within the die cures the resin, resulting in a solid, durable composite product. Each of these stages is critical to the overall success of the pultrusion process.

The Role of Temperature and Pressure

Temperature and pressure are vital in the pultrusion process. The die is typically heated to facilitate the curing of the resin, while the pressure helps ensure that the fibers are adequately impregnated with resin. These parameters must be carefully controlled to avoid defects in the final product, such as air pockets or uneven material properties.

3. The Mechanics of Polyurethane Dies

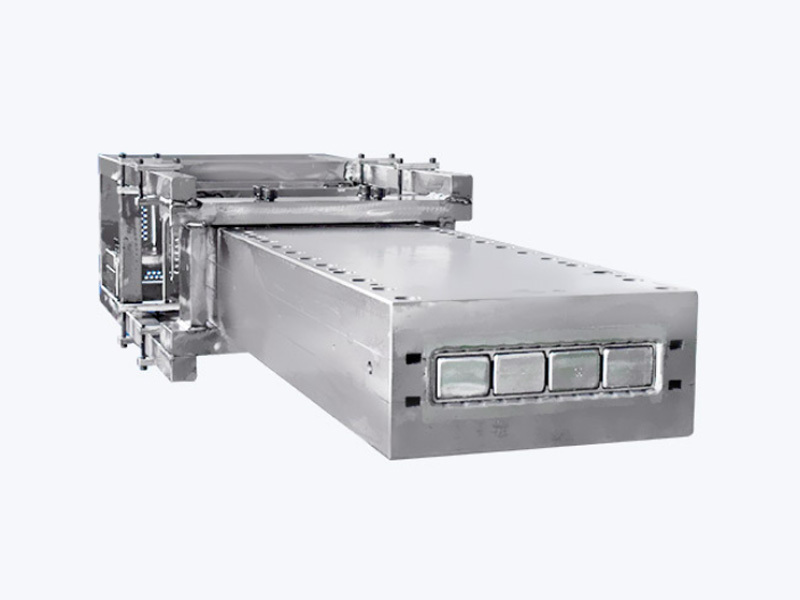

Polyurethane dies are designed to withstand the rigors of the pultrusion process while providing the necessary thermal stability and chemical resistance. The die's mechanics involve various elements, including the die body, heating elements, and cooling systems.

Die Components and Their Functions

The primary components of a polyurethane pultrusion die include:

- Die Body: The structural foundation that shapes the composite material.

- Heating Elements: Systems integrated into the die body to maintain optimal curing temperatures.

- Cooling Systems: Mechanisms for cooling the extruded profiles to solidify the material and enhance production rates.

Flow Dynamics in the Die

The design of the die also influences the flow dynamics of the resin within it. An optimal die design ensures that the resin flows evenly around the fibers, which is crucial for achieving uniform material properties. Computational fluid dynamics (CFD) simulations can aid in analyzing and optimizing flow patterns within the die.

4. Design and Engineering Considerations

The design of polyurethane pultrusion dies requires a deep understanding of both material science and mechanical engineering. Several considerations come into play when designing these dies to ensure optimal performance.

Die Geometry and Profile Design

Die geometry is critical to achieving the desired profile of the composite material. Engineers must carefully consider the shape, dimensions, and angles within the die to facilitate smooth resin flow and adequate curing. The design must also account for shrinkage during the cooling phase to prevent defects.

Thermal Management Strategies

Effective thermal management is essential in die design. Engineers must ensure that heat is uniformly distributed throughout the die to avoid hot spots that could lead to uneven curing. This often involves placing heating elements strategically and incorporating insulation to retain heat.

5. Material Selection for Pultrusion Dies

Choosing the right materials for constructing polyurethane pultrusion dies is paramount to their performance and longevity. Various factors influence material selection, including thermal conductivity, chemical resistance, and mechanical strength.

Common Materials Used

Some of the common materials used in the construction of pultrusion dies include:

- Tool Steel: Known for its strength and durability, making it ideal for high-wear applications.

- Aluminum: Lightweight and resistant to corrosion, often used for less demanding applications.

- Composite Materials: Sometimes used for specialized applications where reduced weight is crucial.

Impact of Material Properties on Performance

The material properties of the die not only affect its durability but also influence the quality of the extruded product. Higher thermal conductivity materials can enhance heat transfer, leading to better curing outcomes. Conversely, materials with poor chemical resistance may degrade when exposed to aggressive resins.

6. Applications of Polyurethane Pultrusion Dies

Polyurethane pultrusion dies are utilized across various industries due to their versatility and efficiency in producing composite materials. Here are some prominent applications:

Construction Industry

In construction, pultruded composites are often used for structural components, such as beams and columns, due to their high strength-to-weight ratio and resistance to corrosion.

Aerospace Applications

The aerospace sector employs these dies to create lightweight structural components that meet stringent safety and performance standards. The use of composites helps reduce weight, which is a significant factor in fuel efficiency.

Automotive Industry

In automotive manufacturing, polyurethane pultrusion dies contribute to the production of components that enhance vehicle performance while reducing overall weight, thus improving fuel efficiency.

7. Advantages of Using Polyurethane Dies

There are several advantages associated with the use of polyurethane pultrusion dies:

Enhanced Durability

Polyurethane dies exhibit excellent wear resistance, allowing them to withstand the harsh conditions of the pultrusion process without significant degradation.

Improved Thermal Stability

The thermal stability of polyurethane ensures consistent die performance across a range of temperatures, maintaining high-quality output.

Cost-Effectiveness

While the initial cost may be higher, the longevity and efficiency of polyurethane dies can lead to lower overall production costs in the long term.

8. Future Trends in Pultrusion Technology

As technology advances, the future of polyurethane pultrusion dies is poised for significant development. One notable trend is the integration of automation and smart manufacturing technologies. These advancements will enhance precision, reduce production times, and improve overall efficiency in the pultrusion process.

Innovations in Die Design

Future innovations may include the development of more sophisticated die geometries using advanced simulation tools, allowing for higher efficiency and better material properties.

9. Frequently Asked Questions (FAQs)

1. What is the primary function of a polyurethane pultrusion die?

The primary function of a polyurethane pultrusion die is to shape and cure resin-impregnated fibers into a solid composite material during the pultrusion process.

2. How do temperature and pressure impact the pultrusion process?

Temperature and pressure are critical in ensuring proper resin curing and fiber impregnation, affecting the final material properties.

3. What materials are commonly used to manufacture pultrusion dies?

Common materials include tool steel, aluminum, and composite materials, each selected based on the specific application requirements.

4. Why are polyurethane dies favored in the manufacturing industry?

Polyurethane dies are favored for their durability, thermal stability, and cost-effectiveness, making them suitable for high-performance applications.

5. What are the emerging trends in pultrusion technology?

Emerging trends include automation, smart manufacturing, and advanced simulation tools for optimizing die design and performance.

10. Conclusion

In conclusion, polyurethane pultrusion dies are integral components in the manufacturing of composite materials, influencing both the efficiency and quality of production. Their design, mechanics, and applications are vital considerations for industry professionals aiming to enhance their manufacturing processes. As technology continues to evolve, the potential for innovation in pultrusion dies remains vast, promising even greater advancements in efficiency and material performance for the future.

PREVIOUS:

Contact Us

Tel:

+86017717930013 +86013621742959

Email:

Address:

No.99 Denggao Road, Motou Town, Rugao City, Jiangsu Province, China.